ABOUT - COAIRE OIL INJECTED ROTARY SCREW

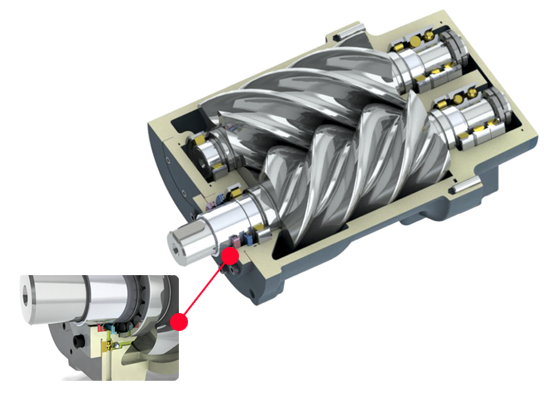

NEW GENERATION AIREND DEVELOPED BY COAIRE

Coaire’s latest version of the Alpha rotor screw compressors were developed in conjunction with Svenksa Rotor Maskiner (SRM), a Swedish rotary compressor designer and manufacturer.

This new design is owned by Coaire for exclusive use. The improved airend as much as doubles life expectancy through lower vibration and reduces sound levels compared to previous models.

FIFTH GENERATION ALPHA PROFILE PROMOTES SMOOTH AND RELIABLE PERFORMANCE

Reduced blow hole design eliminates friction between rotors, thus reducing vibration and noise levels while minimizing power loss.

Improved precision of the rotors by adjusting tooling pressure angle and narrowing the sealing line, while reducing the resistance and space efficiency at the same time.

The thermal efficiency of the Alpha profile is 9% higher than a conventional airend profile.

State-of-the-art machining, casting, measuring, grinding, and testing process ensures a high quality product.

MADE WITH STRONG AND DURABLE MATERIALS

All airends are cast from high quality material produced with innovative technology, equipment, and tooling.

Refined cabinet structure consists of heavy gauge metal (and sound absorbing material) with service-friendly access panels allowing for very low sound levels and easy access for service and adjustments.

G2.5 grade balance control guarantees low vibration and extended life expectancy of the bearings.

Dual bearing structure provides rigidity for the axial load.

High efficiency 3-stage oil seal system for improved leak prevention

MULTI-FUNCTION, USER -FRIENDLY CONTROLLER

Easy operation key-pad

Multilingual (6 languages, including English, Spanish, Portuguese, Korean, Russian, and Chinese)

Pyramid structure menu designed for convenient use

Large LCD panel

Up to 60 journal entries are saved to secure stable operation and thorough protection for your machine.

This user-friendly controller is included.

EASY MAINTENANCE

Easily detached service doors allow convenient replacement of all parts and minimize maintenance time.

Flanged connections use a high quality o-ring design which reduces maintenance costs.

Large oil drain and oil input ports reduce oil change times.

Two visual oil level sight glasses for positive oil level checks

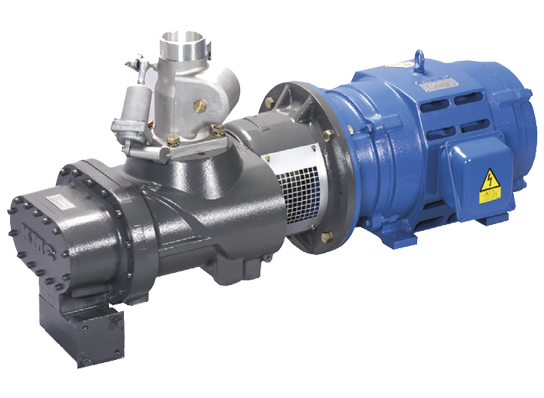

DIRECT DRIVEN SYSTEM

All 30hp - 200hp airends are connected to the motor by a direct or gear driven system.

A direct driven system increases transfer efficiency.

Coaire uses only high-efficiency certified motors.

VARIABLE SPEED DRIVE (VSD) TYPE

Available as an option:

Inverter Bypass System

This option allows air compressor operation when the inverter is offline.

➊ Inverter & Control Box w/Line Reactors

➋ Visual Oil Level Gauges

➌ Separator Tank

➍ Airend

➎ Suction Filter Assembly

➏ Oil & After Cooler

VSD Screw Compressor Energy Savings

Reduced power consumption during no-load operation: quick change rotation speed allows quick and accurate adjustment to the system air requirements fluctuations

Required compressed air = produced compressed air

Reduced unnecessary production of compressed air while minimizing energy loss

Pressure control allows pressure configuration based on the system’s requirements

Soft start prevents power loss from over-amperage and extends motor life.

Inverters are CE and UL certified.

VSD Screw Compressor Applications

Systems with large fluctuations in compressed air demand benefit when:

production line consumption varies

day and night shift air consumption vary

monthly and seasonal air consumption vary

Production lines with future expansion plans

VARIABLE SPEED DRIVE

TOUCH SCREEN CONTROLLER

10" touch screen

Easy to monitor operating status

Data back up saves file in Excel format

Easy setup configuration, operation mode, and controls

Trend analysis of compressed air usage is available using graphs (daily, weekly, monthly)

Operating scheduling

This touch screen controller is available as an option.

MINI ROTARY SCREW

AIR COMPRESSOR

➊ POWERFUL AIREND

• New generation airend manufactured in Germany

• All-in-one style, with integrated suction valve helps prevent oil and air leaks

• High performance parts (suction valve, separator, mpv, etc.)

• Low RPM airend promotes quiet operation and more FAD

➋ QUIET, HIGH PERFORMANCE COOLING FAN

• Durable, high performance steel fan blades

• Quiet rotor

➌ SMART AND INTELLIGENT CONTROLLER

• Supports 2 languages simultaneously (English, Korean, Chinese, Russian, Portuguese)

• RS485 communication , status output (4EA)

• Various alarms and unit protection functions (ALARM: maintenance, high discharge temperature, high discharge pressure), (TRIP: temperature

exceed, pressure exceed, main motor overload, fan motor overload, emergency stop, reverse phase)

➍ COMBINATION COOLER

• Fin tube designed to cool under high temperature conditions

• Cooler designed to withstand 15bar

➎ MAIN MOTOR

• Fully enclosed and insulated motor

➏ ANTI-LEAK DESIGN

• Stainless steel flexible hoses protect against vibrations and oil leaks